Table of Contents

Product development has come a long way since the Industrial Revolution. Precision, efficiency, and innovation are paramount in its landscape. With the advent of new technologies, the product design development process has become more efficient and effective.

One such technology that has revolutionized the development process is 3D design engineering. A paradigm that revolutionizes the way products are conceptualized, prototyped, and brought to market.

The Evolution of Product Development

Product development has evolved over the years. In the past, product development was a lengthy process involving many trial-and-error, manual drafting, and physical prototypes. With the advent of new technologies, the process has become streamlined.

In modern product development, extensive research, design, and testing are crucial. Despite the significant advancement of CAD, its limitation to a 2D space constrains the depth and realism of designs.

The quest for more immersive and detailed modeling tools is ongoing in pursuit of innovation. This paved the way for the evolution of 3D design engineering. The use of 3D engineering has made the process even more efficient.

What is 3D Design Engineering?

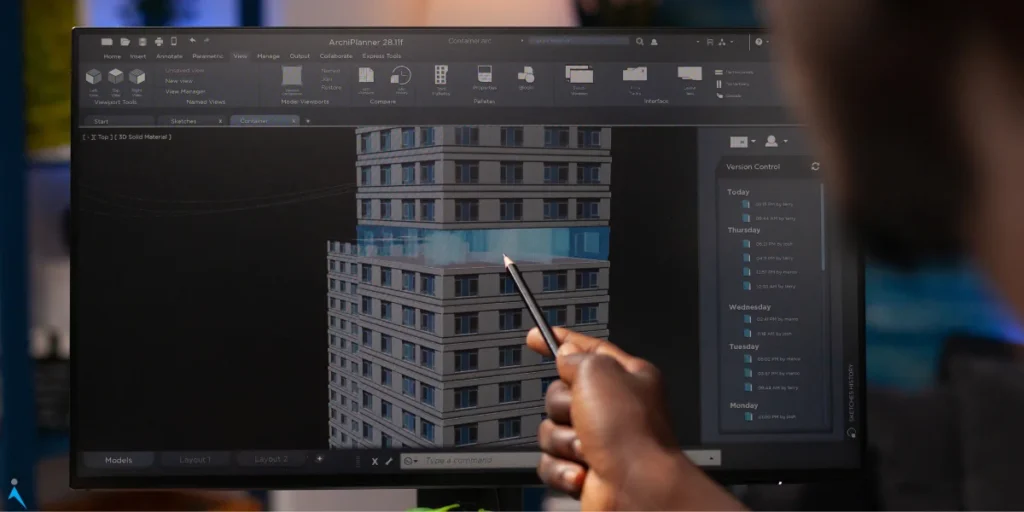

3D design engineering is the process of creating three-dimensional digital models of products. Engineers can use this model to visualize and test the product before manufacturing it. It enables a more comprehensive and immersive representation.

It involves using specialized software to simulate the physical appearance and functionality of a product in a virtual environment. This multidimensional approach allows designers and engineers to visualize, analyze, and optimize every aspect of a product.

3D designs have applications in various industries, including automotive, aerospace, and consumer goods.

Benefits of 3D Design Engineering in Product Development

- Agile Development

Digital renderings respond swiftly to urgent requests, offering personalized solutions globally faster than traditional physical models.

- Sustainability

3D design engineering minimizes physical prototypes. It meets sustainability standards and significantly reduces waste in product design.

- Design Efficiency

3D modeling cuts design time and costs. As a result, it enables comprehensive evaluation of components, testing, and updates before production, eliminating the necessity to begin anew.

- Flexible Prototyping

Versatile 3D designs enable easy product prototype development from various sources, streamlining design assessment.

- Precision and Quality

3D scanning and modeling ensure accurate virtual representation, guaranteeing quality and precision in design implementation.

- Streamlined Design Development

Revolutionizing the product development landscape, 3D design engineering disrupts the cycle of iterative revisions and prototype orders. This transformative approach accelerates the entire product design process, fostering efficiency and precision.

Challenges and Solutions

While the benefits are immense, challenges persist. Integrating 3D design engineering into established workflows can be daunting. However, advancements in training programs and user-friendly interfaces are breaking down these barriers, making the transition smoother.

- Learning Curve

The transition from 2D to 3D design may pose a learning curve for design teams. The investment in training and upskilling is a worthwhile endeavor that pays off in increased productivity and creativity.

- Software Compatibility

Compatibility issues between different 3D design software can hinder collaboration. Standardizing software within an organization or using platforms that support various file formats can address this challenge.

- Resource Intensity

Creating detailed 3D models requires significant computational resources. The latest cloud based 3D softwares can help mitigate resource constraints. These innovative tools streamline and optimize 3D modeling and design processes, offering a multitude of benefits.

Future Trends in 3D Design Engineering

The future of 3D design engineering looks bright. As technology evolves, we can expect to see even more advanced tools and techniques for creating 3D designs.

VR and AR Growth: Affordable virtual reality (VR) and augmented reality (AR) tech will drive the demand for 3D content, empowering designers to create immersive collaborative environments.

AI Efficiency: Artificial intelligence (AI) advancements accelerate 3D model creation, optimizing design workflow and allowing us to focus on creativity.

IoT integration: Internet of Things (IoT) Integration involves interconnected systems for real-time monitoring. This synergy will enhance efficiency, optimize functionality, and foster exceptional innovation.

Role of 3D Printing: 3D printing is redefining engineering with its ability to rapidly create intricate designs. This future trend in 3D design engineering includes innovative applications, cost-effective prototyping, and personalized manufacturing solutions.

Wrapping Up

When it comes to product development, 3D designs help engineering professionals come up with the most innovative solutions. It represents a radical change that aligns with the demands of a rapidly evolving market. As technology evolves, we expect to see even more advanced tools and techniques for creating 3D models.

Skilled design engineering experts at Immersiv Technologies are well-versed in 3D CAD and can meet any design need. You can benefit from highly competitive yet affordable solutions by outsourcing design services to us.

Looking for a new casino site to try. alfabetcassino got some slick-looking games. Time to gamble at alfabetcassino.

777 casino seems like it will never let you down with the classic feel. Not bad at all! 777 casino

2222ph https://www.be2222ph.org

balato88 https://www.balato88u.com

tayabet https://www.yetayabet.net

playpal77 https://www.playpal77sy.org

777phl casino https://www.777phl.org

okebet3 https://www.okebet3u.org

okebet168 https://www.okebet168u.org

jl16login https://www.adjl16login.net

phtaya10 https://www.phtaya10y.com

gkbet https://www.gkbeth.org

slotphlogin https://www.exslotphlogin.net

nustaronline https://www.umnustaronline.org

pin77 casino https://www.pin77-ol.com

philbet https://www.philbetts.net

phtaya1 https://www.phtaya1.org

91phcom https://www.91phcom.net

a45com https://www.a45com.org

mwplay88fun https://www.mwplay88fun.org

taya333 https://www.taya333.org

fb777 slot https://www.fb7777-slot.com

peso99 https://www.repeso99.net

phtaya11 https://www.phtaya11y.com

tg77com https://www.tg77com.org

phtaya01 https://www.phtaya01.org

93jili https://www.la93jili.net

philucky https://www.usphilucky.org

nustar online https://www.etnustar-online.com

jiliokcc https://www.jiliokccw.com

jilivip https://www.jilivipu.net

jilibet004 https://www.jilibet004.org

ph22login https://www.ph22login.org

bet777app https://www.bet777appv.org

I always spent my half an hour to read this weblog’s articles every day along with a mug of coffee.

Ahaa, its good dialogue concerning this article at this place at this blog, I have read all that, so at this time me also commenting here.

Way cool! Some very valid points! I appreciate you writing this write-up plus the rest of the site is extremely good.

99boncasino https://www.99boncasino.net

I am sure this article has touched all the internet users, its really really pleasant piece of writing on building up new weblog.

If you’re looking for a VIP experience, abc8viplogin isn’t bad. It’s a good login option. Easy to use and effective. abc8viplogin

Bingoplusph is my go-to for a quick game of bingo. Easy to use on my phone, which is a big plus! Give Bingoplusph a shot: bingoplusph

Playtimecasinologin is pretty straightforward. No weird hoops to jump through to get logged in, which is a win in my book. Check it out here: playtimecasinologin

jili90 https://www.adjili90.org

I’ll immediately clutch your rss as I can’t find your email subscription link or e-newsletter service. Do you’ve any? Please allow me realize so that I may subscribe. Thanks.

Peryaplay? Man, I’ve been spinning those slots like crazy on peryaplay. Pretty decent payouts, and the site doesn’t lag like some others I’ve tried. Worth a shot if you’re looking for some action.

Betanocassino, eh? I gave it a whirl and the casino games are pretty slick. Decent bonuses too. If you’re looking for a new spot to try your luck, give it a shot: betanocassino

Downloaded the crashercasinoapk the other day. Easy to install, pretty straightforward. The games are okay, not groundbreaking but fun enough for a bit. Check it out for yourself here: crashercasinoapk

pp365: The Best Online Casino in the Philippines – Legit Online Gambling & Real Money Games. Experience pp365 online casino, the best online casino in the Philippines for legit online gambling PH. Play top-tier real money casino games PH and enjoy secure payouts. Quick pp365 register Philippines steps to start winning today! visit: pp365

We are a gaggle of volunteers and starting a new scheme in our community. Your web site provided us with useful info to work on. You’ve done a formidable job and our whole group will probably be grateful to you.

Ahaa, its good conversation concerning this post here at this web site, I have read all that, so now me also commenting here.

[283]J8jili Online Casino Philippines: Top J8jili Slot Games, Easy Login, Register, and App Download. Join J8jili Online Casino Philippines for top J8jili slot games. Enjoy easy J8jili login, quick register, and the J8jili app download. Play and win at J8jili today! visit: j8jili

There is definately a great deal to find out about this subject. I really like all the points you’ve made.

keno-winning-numbers

Stop by my web blog; game (Rich)